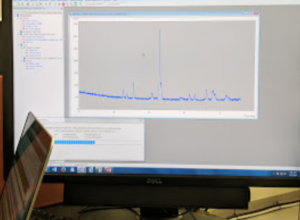

For all that do not know me, I am Ian Enkema, a rising senior at Telluride High School. To start, let me thank Pinhead Institute for being a essential factor in securing my internship at the Joint Institute for Advanced Materials, and Cliff Hawks (CEO of Cherokee Farms) for coordinating and securing this opportunity and a place for me to stay. Since I had just turned 18, it was possible for me to stay at the Hyatt in downtown Knoxville, placing me right in the middle of many attractions. Anyway, my time at JIAM has been incredible. Though my internship is shorter than most (2 weeks), I have been learning rapidly to make up for every minute I am not here. The first day, I was quite literally thrown into the world of material science. Although I didn’t fully grasp all the concepts on the first day, Brianna, my main mentor, introduced me to XRD (X-Ray Diffraction) plots to use as a “fingerprint” of a certain material. These plots can be matched with a credible, accurate database online to show how pure a synthesized material can be, and to check the standard for the ratios of different elements in a pure material. Synthesizing certain materials, or in our case “high entropy oxides”, requires a fine ratio of elements so that there are not any stray elements left in the material that cannot bond, like having that correct amount of reactants to create a certain product. In short, how closely our plots and that of the online database matched showed the amount of error in our procedure. Not only that, but the graph also told us where our error was in terms of energy “peaks” at certain values of theta. I know this sounds confusing, and it’s because it is. It’s much easier to understand visually. Here’s a picture.

The y-value of this graph does not have a unit, it simply shows x-ray concentration in the sensor. The higher the peak, the more concentration.

Concentration is caused by small beams of x-ray light passing through a material and reflecting off into a sensor. In this way, we can measure the certain structure, or unit cell, and lattice of the material. When there is error in matching our plot to a database plot, we know that there is extra, unnecessary material obstructing the x-ray beams.

Phew… that was the first day. I didn’t get all of this on the first go either.

This is the undergrad intern, Quinton, and I scaling out materials to +/- .0002 grams of a certain ratio. It was tedious, but essential.

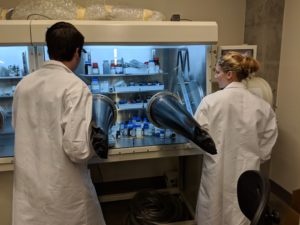

On Tuesday, I went down to a lab with presses, scales, mixers (that isn’t the proper term), and loads of different elements, oxides, and alloys. This is where we synthesized different high entropy oxides. In short, a high entropy oxide is a inorganic material that contains many different elements to create randomness within its properties. This is alike high entropy alloys, which were recently studied and found to give various unique properties. Unlike high entropy alloys, high entropy oxides have had little study. Scientist believe them to be a material of the future. So hey, the stuff I am a part of here is actually really neat. I suggest any of my readers look at this video for a visual representation of cool properties in different advanced materials: https://www.youtube.com/watch?v=Mo1lDsESD90. Although the materials that we are synthesizing don’t give properties like those in the video, they are equally unique in nature.

Wednesday was much the same, but in the afternoon, Brianna took me over to some of the labs at the University of Tennessee, Knoxville. I got to see an application of unit cell structure in that materials could become stronger if a crack could not easily pass through its atomic structure (intercepting at a certain point). This is where randomness, or “entropy”, helps improve the durability of the material. I got to see a machine which calculates properties of durability by applying stress to stacked polymers. These certain polymers used in the experiments were designed to split evenly along a certain path.

This is a computer generated model of the experiment I watched, and animates the split along the middle of the polymer as predicted.

On Thursday, Quinton and I spent the day in the lab synthesizing, grinding, and pressing materials into a pellet that could be furnaced at very high temperatures to get the elements to bond into a single material. If the elements that make up the material were not ground up, weighted, pressed, or furnaced well enough, the material would be less pure, resulting in more noise and less resemblance than the database XRD plot, or there would simply be more errors.

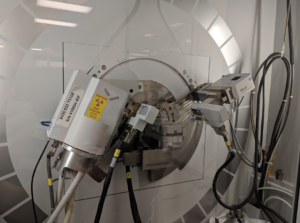

This is a hydraulic press. We would press the materials, which are located inside of that big cylinder, with the rod on top of them. This would form a 1/4 inch pellet, in which we pressed at 3 tons (the safe maximum for that diameter, and I don’t want to break anything in the lab. The price of a something so small would shock you, and this is a big press, so…)

On Friday, we enjoyed a day out of the lab at a beautiful hike at Alum Cave. It surprised me. I had lived in Tennessee for most of my childhood, and had never known of any terrain as beautiful and massive as this region. The trail was rich with beautiful flowers, foliage, and mushrooms. As we climbed to the top, the elevation gave me a sense of home, being in the mountains.

I love how abnormal this bridge is. It compliments and blends with the environment and nature so well.

This concludes week one of my internship with JIAM at Cherokee Farms. I have learned so much and I am sure that these fundamentals of material science will apply in any STEM field that I might venture into. Again, I would like to thank Pinhead Institute for having a program to make this opportunity possible, Cliff Hawks for being very active in securing this internship as well as helping me with any other problems I may have had, and many others who have assisted along the way.

There are no comments published yet.