My time here is quickly coming to an end. Although six weeks seems like a very long time for me to be gone it is almost nothing in the scale of this project and honestly it astounds me. So many people have been working towards the completion of this project (Over 50 people including students and professionals) for so long (over 3 years) and I am honored to be a part of it. This week Sid, Bena, and James who I normally work with are all gone so I have gotten to spend a lot more time with Tom who is basically a superhero here. This Monday he sat down with me and talked about what we needed to get done that day. The main thing was putting screws into the CDH and motherboard so they could be sent off to conformal coating. This is when they cover the board in a layer of plastic so nothing can move or get shook loose. Tom gave me a lot of responsibility as a highschool student and let me work on the boards on my own while he was in meetings. This was kinda cool because I felt like Tom had a lot of trust in me and I was doing something that was really productive for the team. Before he left we looked at the boards and decided that we needed some longer screws and some tools that weren’t in our shop (Really small wrenches) to finish the assemblies. So tom went with me to the Machine shop and helped me find the screws and whatnot before he went off to his meetings. Then I cleaned the screws that needed to be cleaned and went to assemble the board. Everything was going really well until I tried to put the standoffs in. Tom told me everything had to be flush to the board so when the standoffs tightened up I kept trying to put them in instead of stopping and asking what was wrong. I ended up shearing off a standoff inside of a connector which sucks because you can’t use that connector anymore. I told Tom and I was really nervous he would be really upset but he was very understanding and told me to stop beating myself up about it. We went to look for an extra connector but it turns out we hadn’t ordered any. He told me not to worry about it and that he would order the connector that afternoon. We finished the rest of the assembly for the boards and gave to CDH boards to the people who are going to conformal coat it. It was sad that I messed up but it turned out to not be that big of a deal but I did a good job on the rest of the boards and I was happy with that. The next morning Tom said that he had tried to order the correct length standoffs but they didn’t sell them at that length anywhere so he told me that we would have to grind the standoffs down to length. This seemed kinda odd that the connectors needed standoffs that aren’t made by anyone but he said it happens all the time when building rockets and stuff so changing screw length wasn’t that weird. We went to the machine shop and Tom showed me how to use a hand tool to cut the standoffs to approximately the right length and then he showed me the fine grind wheel and how to use it to make the screws a little shorter and have even tips. I technically wasn’t supposed to use this machine but Tom is so highly respected here that his word was enough to authorize me. I then put them through a “dye” (I’m not sure how to spell it) which made sure that there were no burs in the threads of the standoff. So I spent some time fashioning the correct length screws then Tom and I put them into the motherboard so now the only thing we had left to do on the motherboard was replace the connector I broke. Tom then told me I should email James and ask him how I could improve the graphs for the Nanoracks testing and James told me some stuff that I should do and I set out to do it in IDL.

Me putting a standoff through the “dye”

A look at my handywork

The Grind wheel I used

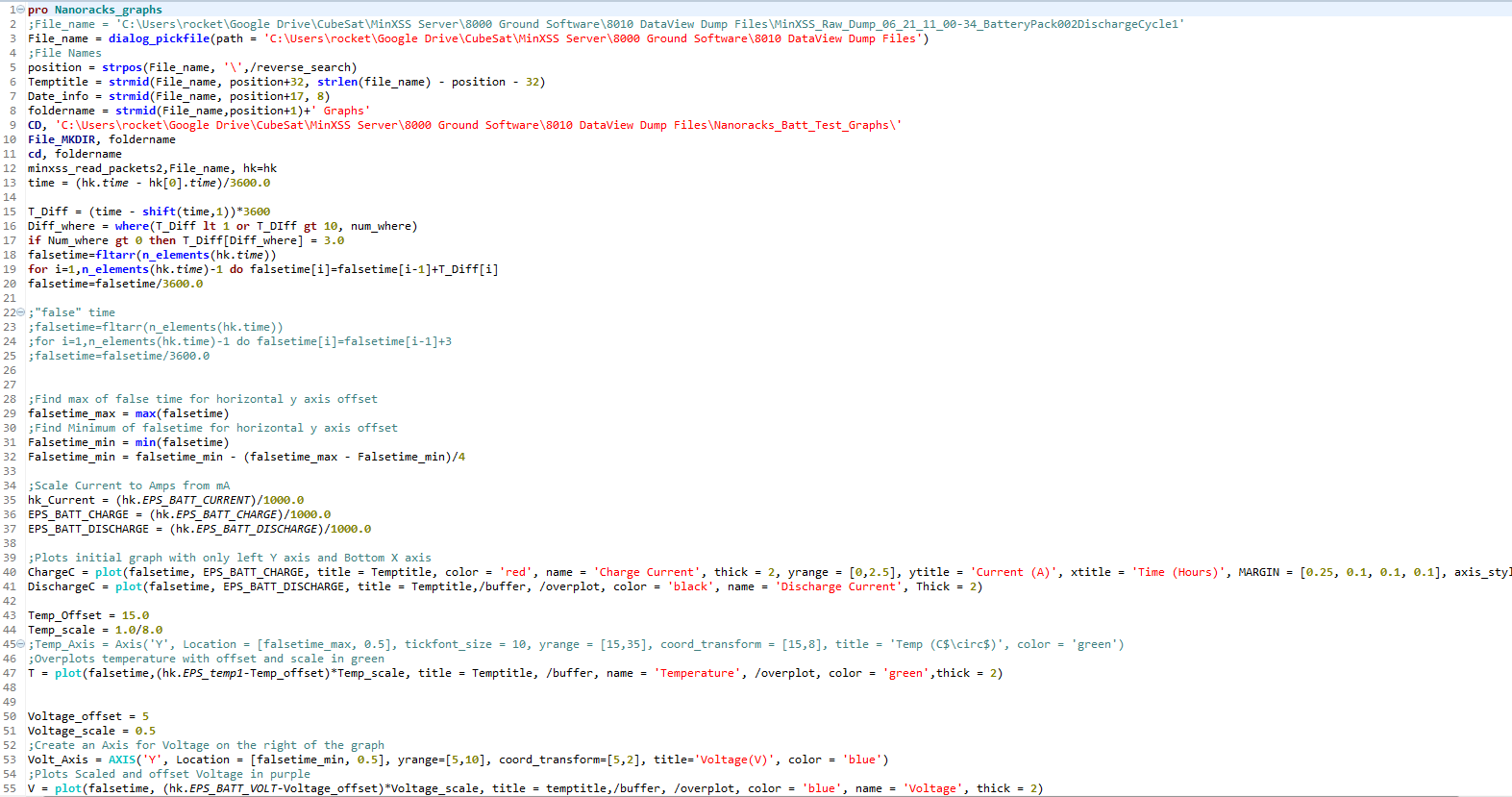

On Wednesday we had another person working on the project arrive from a fellowship at the Jet Propulsion Laboratory. His name is Chris and he is a really nice guy. He has a lot of experience with IDL so Tom asked him to help me with my project. I spent the entire day working on this with Chris helping occasionally. Coding is really difficult, but it is necessary for a lot of things in this field. Also it isn’t super interesting for you guys to listen to so I’m just going to put a picture below of the code that made between Wednesday and Thursday.

On Wednesday we had another person working on the project arrive from a fellowship at the Jet Propulsion Laboratory. His name is Chris and he is a really nice guy. He has a lot of experience with IDL so Tom asked him to help me with my project. I spent the entire day working on this with Chris helping occasionally. Coding is really difficult, but it is necessary for a lot of things in this field. Also it isn’t super interesting for you guys to listen to so I’m just going to put a picture below of the code that made between Wednesday and Thursday.

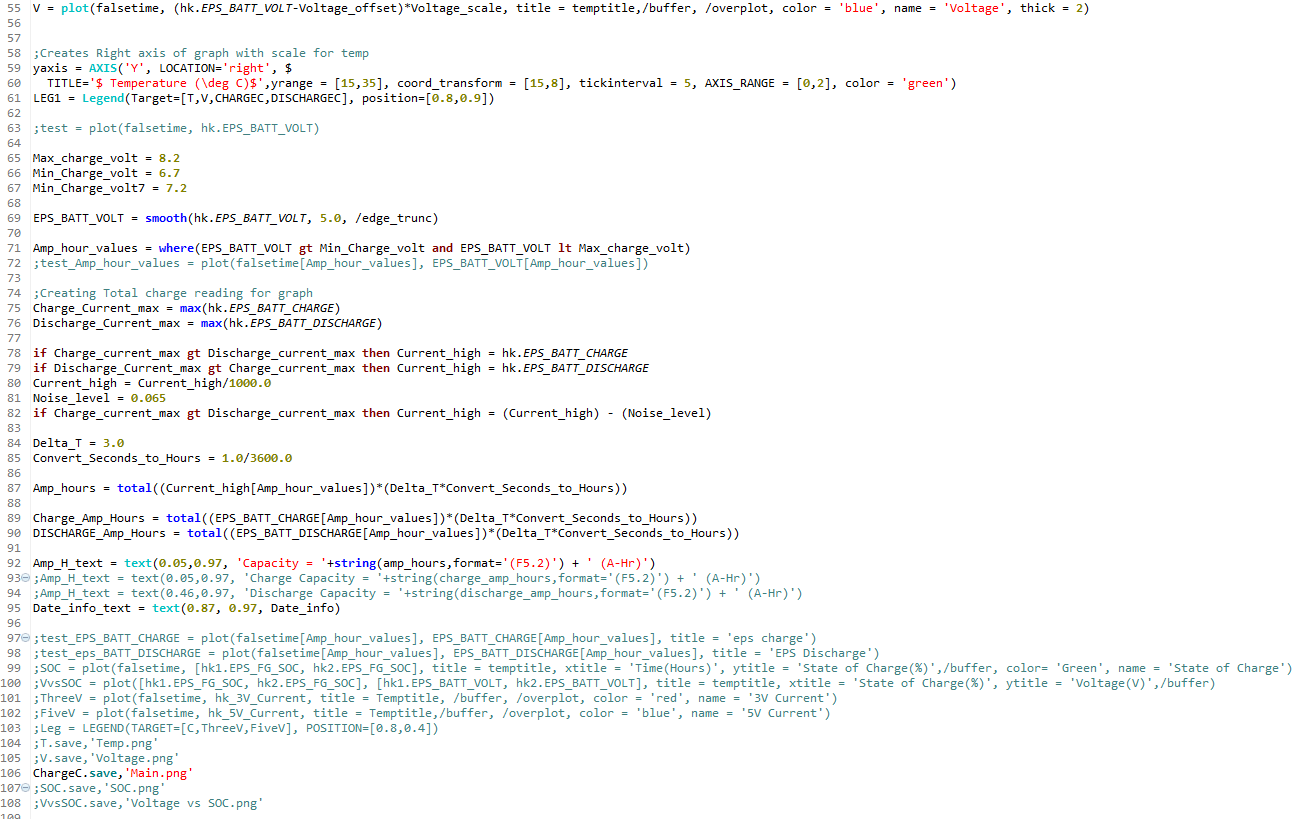

This took up most of my time of Thursday too.In the end though it will be really useful for anyone else that wants to make graphs of the housekeeping data and to save space on the report to nanoracks. What the code does is it references a code that Tom wrote which turns the raw hex data into actual readable data. Then it takes the information and puts it into a graph. It also calculates the Amp hours that the battery had during that cycle and puts it on the graph. Then it creates a folder and names it based on the original file name and saves the graph in that folder. It doesn’t sound that complicated but it was actually really difficult and took almost two whole days to do. It would have taken longer for me if Chris hadn’t helped too. Also the new connector arrived on Thursday so we were able to send the Motherboards in for conformal coating.

This took up most of my time of Thursday too.In the end though it will be really useful for anyone else that wants to make graphs of the housekeeping data and to save space on the report to nanoracks. What the code does is it references a code that Tom wrote which turns the raw hex data into actual readable data. Then it takes the information and puts it into a graph. It also calculates the Amp hours that the battery had during that cycle and puts it on the graph. Then it creates a folder and names it based on the original file name and saves the graph in that folder. It doesn’t sound that complicated but it was actually really difficult and took almost two whole days to do. It would have taken longer for me if Chris hadn’t helped too. Also the new connector arrived on Thursday so we were able to send the Motherboards in for conformal coating. On Friday Tom and Chris weren’t going to be in the office and Tom didn’t think that Bena, Sid, or James were going to be here today so Tom told me I could just take the day off. So I came in to finish my blog and them I’m going to go see the new TMNT movie later today. And actually as I was typing this Sid showed up so I am not sure whats happening today but I am sure it will be enjoyable. I have one week left and I can already tell that I am going to be so sad to leave. I hope everyone reading this enjoys themselves and you will here from me one last time after this. Bye!

On Friday Tom and Chris weren’t going to be in the office and Tom didn’t think that Bena, Sid, or James were going to be here today so Tom told me I could just take the day off. So I came in to finish my blog and them I’m going to go see the new TMNT movie later today. And actually as I was typing this Sid showed up so I am not sure whats happening today but I am sure it will be enjoyable. I have one week left and I can already tell that I am going to be so sad to leave. I hope everyone reading this enjoys themselves and you will here from me one last time after this. Bye!

Thanks for all the blogs Marten. It is interesting to see how it is going. We are all interested in the progress now and look forward to the launch and the data it receives.

I have no idea what you were talking about, but I could not be more proud.xox

Amazing patience Marten! You have the detail oriented gene! I get it! Carry on!

Much Love, Jessie

Marten,

Go Marten, GO!!!

You sound like you are right in your element. It sounds so wonderful to read your passion for assembling….keep the enthusiasm, it will get you far in life! Thank you for sharing.