This is my third week at the University of Houston studying Chemistry! This week was full of strange things I had to face, and I learned a lot from this week. The week started off confusing and full of confusion, and eventually sorted itself out with some thinking involved.

Monday and Tuesday, June 19th, and June 20th was spent attempting to filter out the rest of our solution with a syringe, even after filtering with a funnel filter. We thought that this would be an incredibly slow way to filter our solution, since I was only getting a few mL every 10 minutes. Professor Baldelli given me the idea to use the centrifuge for our solution, so we could remove any of the precipitate that had formed in a faster, and more efficient way. Our first tries at this was unsuccessful, but once we cranked the speed up to full, and the time to maximum, we found results at the bottom of our solution. I was able to take a pipet and move the clear solution to a clean beaker, where we wouldn’t have to deal with that other material in our solution. Unfortunately, I did have to put our syringe filtered solution in the centrifuge anyways, since there was no guarantee that it would be clear. Honestly, I was just happy that it had worked.

We measured our the rest of the Indium Chloride that we received onto our weighing paper (avoiding the aluminum foil), and found that the number did not in fact, equal the amount we were supposed to have onto the bottle. We thought the place we had ordered the chemical from had not given us several grams that we had paid for. After weighing everything, including the bottle, we realized that it was not the companies fault, but instead ours. The scale had been wrong since the very beginning, and that was the most likely reason our experiments were so cloudy and unfilterable. The day I weighed out the Indium Nitrate, I was skeptical that it was only 4.24g, but I went along with what the scale said, and I should not have. Not all was lost however, we found a few weights where we could see exactly how much 5g, 10g, 50g corresponded to on this scale. With this information, we formed a graph of the scale relative to the real weight, and then tweaked our solutions molarity from that. Instead of a 0.2M solution of Indium Chloride, we had a 0.47M, and instead of a 0.1M Solution of Tin Chloride Tetrahydrate, we had a 0.23M solution. With these new calculations, I was able to set up my dilutions for Wednesday.

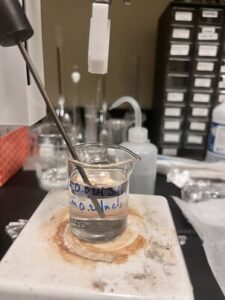

Wednesday and Thursday were very similar days. Wednesday was mostly spent creating the solutions with our stock solutions, and finishing up the centrifuge filtrations. Creating these solutions took precision, and I was incredibly nervous doing this, since we did not have any more material to work with, other than what I had in front of me. At the end of the day Wednesday, I had everything ready for dipping, and I had thought I would be able to dip that day, but there’s always something that comes up no matter how well you plan ahead. One thing that did come up was our thermocouple was not reading the correct temperature, making me go back and find a new one, so we wouldn’t make a similar mistake to last time. (I did make another mistake with this) While waiting for the solution to warm up to 60C with the broken thermocouple, I had overheated it and some reaction had occurred, causing one of my solutions to again turn cloudy and unusable. However, I was able to make a new solution with our leftover stocks. Thursday I began dipping, the process was tedious and full of waiting. I had to wait for the

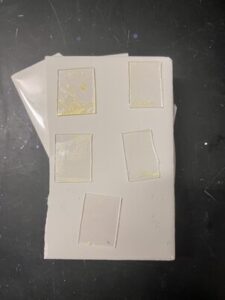

solution to warm up on the hot plate (60C), then put the substrate into the solution, having it slowly pull out at only 2mm a minute. This entire process, for all 5 slides, took forever. After I finish dipping, I need to put these glass slides into the furnace at 500C for 10-30 minutes. Afterwards, this first batch of slides came out yellow, and the solution that came out cloudy did not create a good film. This was all I had time for on Thursday, since a whole batch of dipping takes at least 3 hours to do.

Friday and Saturday was mostly spent doing the second round of dips, third round of dips, fourth round of dips, and fifth round of dips. Because this batch of dipping substrates were flawed, we were going to make more with a different approach, more akin to the paper we were following. On Saturday, I begun making a styrofoam insulator for our solution and substrate, since both should have been heated to 60C as opposed to only the solution. We were also going to fire our substrates once we finished dipping under Nitrogen gas to follow the paper more precisely, in hopes of better results. During this time, I was taught how to use the UV/Vis spectrometer to analyze the films and see how similar they are to the paper’s. I took the remaining data and filed it away for future use.

This week was full of different things, and I was incredibly happy to learn so much in such a little time.

There are no comments published yet.