Monday was a celebration for the other high schoolers’ departure. We went to the airfield to shoot off the rockets we had made previously and to have a cookout. It was fun talking with the other kids and seeing everyone there. When we started launching rockets the wind was worse than it had been the whole time I’ve been in Oklahoma. This provided a fun opportunity to learn. The first rocket shot off went close to 2,000 feet in the air. After it separated and deployed its parachute the wind took the body probably a mile away. To prevent this happening to our rocket we ripped our parachute in half in order for it to fall at a faster rate while still slowing the body down enough for it to land safely. We recovered our rocket fully intact after a successful launch. One interesting thing I learned today was that rockets need to be a certain level of unstable unless they’re perfectly stable. As we saw from another team’s launch, an overstable rocket is prone to having its bottom being swept out from under it and then continuing on that new sideways trajectory. Instability helps the rocket to recover a vertical path after being affected on by outside forces. This was a very backwards concept to me and it sparked a great conversation with a rocket expert and enthusiast. I was able to ask a ton of questions and he was extremely excited to tell me about special things on rockets such as the Falcon-9 as well as some military missiles.

On Tuesday Micah and I started a new project of building a plane from a kit. We were supposed to only make it a glider because the kit didn’t have electronics for rc, however we decided it would be more fun to scavenge for parts and make it flyable. The actual build of the body was pretty hard as we were trying to make it as precise and clean as possible. We finished the body of the fuselage and the tail as well as adding push rods to the elevator and rudder that connects to servos in order to control the rear of the plane. On top of the plane build we helped test the solar cell project. We needed to test its insulative ability as the box will reach 80,000 feet where the temperatures are usually around -50 degrees celsius. During the day we turned the electronics on inside of the sealed box and placed it in a freezer that got to -45 degrees celsius. The box was in for close to 5 hours before it shut off.

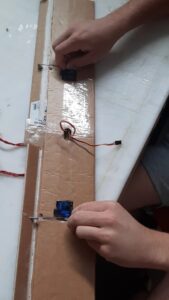

Wednesday was a continuation of the previous day. We continued the build and completed wings for both a glider build and the rc version. We also implemented servos to control the ailerons in order to tilt the aircraft. Today I learned a ton about servos and also had a new view into the functioning of aircraft. On top of adding rc controls we decided to dry to add landing gear. The normal build only uses the floor of the fuselage to land, however this creates an issue as the nose is at an unsafe level to the ground which runs the propeller into the ground and can lead to damaging the props and motor if the landing is done at a less than perfect angle.

On Thursday we finally finished the plane and then started to fly it. It was very steady and AJ, an expert flier, said it flew better than the normal kit due to added weight. Micah and I got to try and fly it but we were pretty awful. The controls are inverted of what your mind thinks and with such a light aircraft the wind affects it a ton. However there is a drone flying simulator in the lab so Micah and I practiced on it a lot. The second time we flew it we were both able to do a few turns and keep it in the air for about ten seconds before we lost it.

After completing the kit plane we were then given free range to design and build our own. We first brainstormed a couple ideas and decided we wanted to build a plane that we could fly a lot through a bunch of crashes. We were going to try to use a push prop behind the fuselage so the the props would not be hit during a nose dive, however after talking to AJ we learned that push props are extremely hard to build because the prop needs to be angled because its moment is affected which is a statics calculation. So instead we were going to try and build a bi plane (stacked wing) and make it out of extremely durable materials like foam and carbon fiber. We finished most of the fuselage by stacking three cuts of foam and then rounding the corners. We also flew a lot of the flight simulator.

There are no comments published yet.