This week I started out by making a DAC board for collecting data. These circuit boards have elevation instruments and upload data on memory cards. I had to solder all of these parts onto a UNO board, the base of the DAC, and ensure my soldering was clean and uniform. If the soldered prongs touched then it would short circuit and become faulty. The most challenging thing about soldering was not burning yourself. The soldering iron that applies heat to the soon-to-be soldered prongs can reach 500 degrees Fahrenheit! One touch from the iron and your skin will be crispy! I worked on my soldering proficiency both Monday and Tuesday.

On Tuesday, I worked on my personal project and finalized the model for the prototype phase. During this phase, you can request a 3D print from the college through their Aeropoint requesting system. This system helps the machinists keep requests organized and chronological to their request date. After I finished my project, I continued working with my mentor on videos and practicing my soldering.

On Wednesday, I put my request in for the 3D prototype and talked with Gerald about some of the design specifics. When you need to 3D print something from SolidWorks, you need to change the files into STL files. These files are triangulated for an easy printing procedure. Some of the important design specifics when 3D printing a prototype is the actual viability. Sometimes, a part can’t be 3D printed for a large list of reasons. One of the important ones is sizing. it’s important to understand sizing because parts can become brittle or messy. On the flip side, 3D printers aren’t very user-friendly and can mess up important specifics for the smallest reasons. So it’s a gamble when it comes to quality.

On Thursday, My prototype finished printing and I was able to start assembly! I made 1/4 inch holes in both the base and gears for easy assembly and filed down the reductions in quality due to printing errors. The end product was bigger than I imagined, with it being 4.5 in. by 2.5 in. In the beginning, I wanted it to fit on a key chain. But, that was scrapped after I saw how big the print was. If I really wanted it as a keychain, I could scale it down to 1:3. The only problem is the thickness of the gears would be nonexistent. They would be brittle and easy to break.

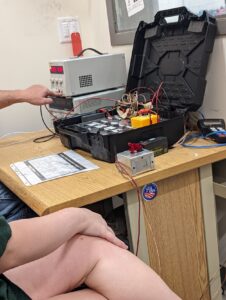

On Friday, Shae and I got to make thrusters for a lab they do in the fall and spring semesters. In the lab, teams make thrusters and predict the amount of thrust their part will make. we got to fire the thrusters and made sure data was being collected by the DAC. The test is done in a Test Cell where they have all the gas and valves already set up and connected. to start the launch, we needed to pressurize a fuel cylinder to 22k psi (I don’t remember the exact number) using the liquid fuel and low-pressure CO2. After the fuel cylinder is pressurized, a beginning burn is triggered using electricity and steel wool. With a light flow of O3, the ignition fire burns strong. Afterward, The O3 valve is quickly turned off as the Fuel cylinder is opened manually by a pulley. The person who pulls the pulley is outside the building through garage doors on the north wall. The actual ignition and burning of the liquid fuel was a sight to behold. it can’t be caught on camera, but the gases being exerted from the exhaust are so fast that they break the sound barrier. This makes a diamond shape to the visual eye. After the two thruster tests were complete, we checked the DACs to make sure they collected data. Unfortunately, it failed to collect data so we never got to see how much lift our thrusters made. Nevertheless, I really enjoyed the lab and watching the insane dynamics of supersonic exhaust.

This weekend, I drove to a 7-on-7 tournament in which Blitz was participating. Blitz is one of the sons I’ve grown close to in the temporary family I lived with for a weekend. The football tournament had multiple schools participating and Blitz was playing with a team full of 13 and 14-year-olds against Varsity level high school football teams. His team came 2nd place against guys both stronger and larger than them! It was a spectacle to watch them play and it was fun to cheer them on!

This is amazing! Well done!!