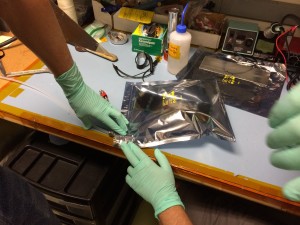

Hello everyone reading my blog. It’s the end of week four meaning I am already two thirds of the way done with my internship. This seems crazy to almost be leaving because I’ve been here for an entire month but my time is more than half over. This week was actually pretty exciting. On Monday we decided to do a thermal cycling test on a solar panel that is assembled but will not be being used for flight. The main thing we are testing was a silver epoxy being used to bind the solar cells to the panel. In the new solar panel design there are three holes in which the silver epoxy goes in and we need to press down on it with a lot of weight for 24 hours but with this old panel there is only one hole and we didn’t leave the weight on for nearly long enough. We still decided to use this panel to see if even with these shortcomings the panel would hold up. First we cleaned the panel then we placed it in an ESD bag. Then we put a hose of Nitrogen into the bag to try and circulate out all of the air and more importantly moisture. This was because moisture around or in the solar panel will freeze when we take the panel to the cold extreme and when this water freezes it could be between two important elements and push them apart. So after we had a bag with our solar panel and nitrogen in it we took it to one of the ovens in the LASP lab. We then took the panel up to 120 degrees Celsius and then down to -60 degrees Celsius. These are the maximum and minimum temperature we expect to see in flight. The solar panel came out unaffected. We couldn’t tell a difference between the panel before and after the cycle. However the zipper on the bag it was in did melt. This was a good thing because it reassured us that even with a panel that was not assembled correctly the panel still stuck together. On thing that I found crazy was the price of the solar cells. These are fairly small cells but they have 30% efficiency which is very high for solar panels so each one of these small cells costs 300 dollars. Meaning this non flight board we were testing on still cost 1,500 dollars which to me was a lot of money. In total we have ordered 50 solar cells which costs a total of $15,000.

Filling the bag with Nitrogen. The panel in the oven. A better view of the oven.

On Tuesday all of our helicoils arrived. I can’t remember if I already explained what helicoils are in an earlier blog so I’m just going to explain them again. They are these things that kinda look like springs and go into holes before screws to give more surface area and a surface harder than aluminum for the screw to grip onto. They essentially make the screws stay in the holes better. So we received a bunch of these and since they are going to be flight they have to be cleaned just like the screws. There was much less helicoils than screws but I still had to take some time to sonic clean them. Then Bena and I tried to go to the machine shop on main campus to work on the tabs for the solar panels but the shop was closed because the guy who runs it was on vacation so we didn’t really get anything done.

Wednesday was also a little bit of a short day because the undergrad that was working on the project with us was leaving on Friday and she had to give a presentation of what she did that afternoon. So in the morning Bena and I did a test on the radio. I did most of the test while Bena kinda watched over me to make sure I didn’t mess up. What I did was I would change the power setting on the radio then check a bunch of monitors that would read out the voltage, current, temperature, and output power of the radio. I would then put this information in an excel sheet that did some algorithm and came up with the efficiency of the radio. This was just to make sure that the power setting we were using for the radio was the most efficient one we could use. This took most of the morning. Then after lunch Sid, Bena, and James were all working on stuff for a smallsat conference in Logan Utah and I couldn’t do much to help so I went and listened to the presentations from all the REU students who were presenting that day. So I listened to a few of those which talked about projects such as creating a warning system for GPS inaccuracy in certain areas based on solar activity and things such as that. Then Christina presented about Minxss and James gave her a aluminum award with all the logos and her name laser engraved on it. This was pretty cool but it was also a little sad that Christina was leaving.

Thursday I was feeling a little bit under the weather but I decided to come to work anyway. In the morning we talked about GSE (Ground Support Equipment). What we mainly went over was a polycarbonate case that Sid was designing to do a full test on the Satellite. We changed the way we activated the satellite initially and changing the routing of some wires to make it more efficient. Then James, Bean, and myself went to the lab to start the construction of one of the solar panels because the solar cells had come in. I basically stood and watched and handed them stuff because of how expensive and difficult the process is. Like always something wasn’t fully prepared and this time we didn’t have the right nuts so we postponed the integration. That afternoon Tom had me working on labeling and organizing a bunch of electronic parts for the integration of the CDH board. I mostly finished but I was feeling really bad at this point so I went home a little early to drink tea and sleep.

I hope up the next day feeling much better and went off to work. Sid, Bena, and James had all left for the smallsat conference so Tom just had a quick meeting with me and talked about what I should do for the day. I started off by finishing up the labeling I had been working on the day before in the morning them Tom and I went to a poster showing and Barbecue for the REU students. There was a lot of really cool projects and free food which makes everything better. Then Tom and I took pictures of the CDH board and the Motherboard (More of a backboard but we call it the motherboard) and he showed me how to do the Flight Assembly Instructions (FAI) for the person that will be staking and conformal coating those two boards. Thanks again for reading my blogs and I was a little brief this week so if you have any questions feel free to ask them in the comments. Talk to you next week.

There are no comments published yet.