Last Weekend everyone from the team went on a group bike ride together and it was pretty awesome. My dad also came out to visit me and we went camping at Estes park and went hiking and swimming in alpine lakes. It’s incredible how little I have explored the front range considering how close I live to it. I had an amazing time but I was ready to get back to work.

My game face.

This week has been a complete whirlwind for me. Monday started off as usual with out morning meeting and that day I was placed with James to continue some of the endless battery testing. We had the new batteries in and we tried to find a combination of batteries that would give us the optimal range on the MOSFET switch. This would mean the MOSFET activating higher than 8.4 Volts but not so high that the batteries were damaged and then the MOSFET closing the circuit as close to 8.4 Volts as possible because the solar panels may not output a Voltage much lower than that. So we spent some time trying different combinations of batteries and we found a certain combination that seemed to work decent. We then left this combination for later testing and went to a teleconference with NanoRacks the company who will be sending us up to space and the ISS. During this meeting we went over a lot of our deployment protocol and NanoRacks brought up concerns they had about our design as well as requirements they had given us that we were yet to reach. One thing that I found interesting but not necessarily surprising was that every element of the deployment process had to have at least one backup mechanism and critical functions need at least three. An example of this is that our deployable solar panels. The primary release for them is a mono filament (fishing line) wrapped around the solar panels as well as a resistor. Ideally the cubesat will slide off the rails of the cubesat launcher without the solar panels deployed. Then we will direct some power from our batteries through the resistor which will turn that current into heat and burn through the fishing line to release the spring loaded panels. However if this wire was to break inside the launcher somehow there are going to be small bronze tabs that protrude literally a few thousandths of an inch farther out than the solar panels which will collide with the rails so the solar panels don’t. Then hopefully the cubesat could slide out of the launcher and have the solar panels instantly deployed. We have a similar system to release out antenna expect there was no secondary plan so NanoRacks is making us simply put two mono filaments around the resistor and over the antenna deployment cover. The only thing we ran into that will caused a real issue and needed redesigning was that we were told our design for launch safety on the EPS (Electric Power System) board was not good enough because we had three mechanical switches for safety but only two MOSFET switches. This made it so Tom had to redesign the EPS board. This took a long time but was very important for knowing what we need to do before delivery to NanoRacks. After that meeting James and I went back to testing the batteries and recharging ones we thought were weak before finding they were some of the highest we decided something was amiss. After some sleuthing we found a poorly soldered cable which essentially made most of what we did that day invalid which kinda sucked. In retrospect however I can say at least we found the problem.

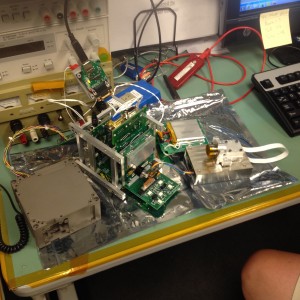

The next day the main goal was to try and conduct a mission test on all the hardware we had to check for bugs in the flight software. The main thing we ended up testing was how well (if at all) the flight software could cycle through the three functioning states. Phoenix is the mode that the satellite initially goes into and the mode that it goes into if it gets very low on battery or something happens. It’s called phoenix because this is the mode the satellite goes into to be rebooted (or “reborn from ashes”). The satellite then moves into safe mode which is when none of the science instruments are functioning but the radio is beaconing and the orientation of the satellite changes from the best angle for science to the best angle for charging batteries. This happens if the batteries drop below around 80% capacity. When the batteries are charged enough it switches to science mode where all the science instruments turn on and the angle of the satellite changes to collect better data. As with all code even that written (even by doctors) there were bugs and this testing took basically all of the day and into the next day. There is a readout called the “fuel gauge” that is supposed to tell the percentage of the battery however it is not very accurate at all so Tom had James and I create our own calculated state of charge based on the voltage and this helped a lot with the tests because they now could get an accurate reading for what 80% charged was for example.

The set up for the mission test.

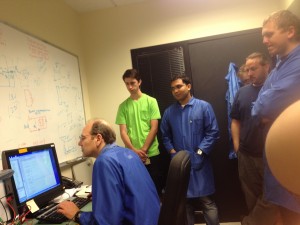

People watching the mission test.

On Wednesday morning we had all the screws in that we needed for the assembly. However after consulting the head mechanical engineer at LASP we decided to replace some of the structural screws with A286 steal instead of the 18-8 that we were using. This meant returning about half of the screws. We still had a load of screws with us as well as fasteners, spacers and PEM nuts. Sadly someone had to spend there time making sure everything arrived and creating an organization system in boxes we ordered for all the bolts and fasteners. Being the Highschool intern I took the job and although it took a lot of the day and was relatively mindless I got to use a label maker and that basically made up for it.

On Thursday I took a day off to go and visit a bunch of members of a camp I attended last summer. There was about 25 people there and we had an amazing time. Although I was missing out on some awesome satellite work I am really glad I took the time to see some people I rarely get to see.

When I returned on Friday I had another task with the screws that took me basically the entire day. What I had to do is what is called sonic cleaning the screws. For those of you who may be unfamiliar this involves putting water in what looks like a shallow bread maker then placing screws in beakers with alcohol in the water. The water serves as a medium for sonic (sound) waves to travel from the sides of the machine into the alcohol and shake off anything and everything that might be on the screws. This was really cool to hear about and I was actually kinda excited to do it until I learned it made noise similar to a prepubescent wasp with a megaphone. I’m trying to say this thing was loud and high pitched and I spent four hours in the same room as it. All and all it was good that I got it done and it was actually kinda enjoyable to do. Everything I have done here has been amazing and I am so glad I got the chance to do it. Although I have no plans for this weekend other than sleeping I’m sure I will find something to do. Thanks to all of you spending your time to read my blog and I’ll be sure to update again next week :D.

thumbs up marten proud of you mk

Thanks Grandpa. That means a lot.